PROMIG 250SYN Pulse

Simple, Synergy, Pulse MIG welding

Application:

Metal Fabrication

Maintenance and Repair

Auto Body,

Light Industrial, Workshop

Processes:

Pulse MIG for AL

Advance MIG for M.S/S.S

Lift TIG

MIG/MAG

Flux-Cored

MMA(Stick)

Input Power:

1PH ~ 230V ±15%/3PH ~ 400V ±15%

Amperage Range: 10-250A

Rated Output at 40℃ (104℉):

250A at 26.5V @60% Duty Cycle

Weight: 32KG

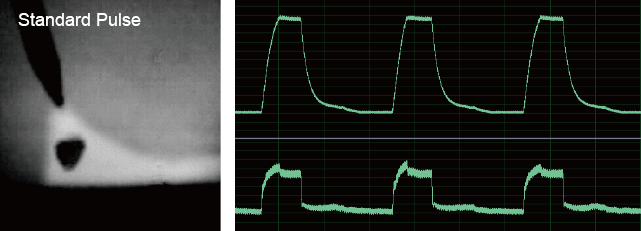

Excellent Pulse MIG Performance

The Pulse MIG process works by forming one droplet of molten metal at the end of the electrode per pulse. Then, just the right amount of current is added to push that one droplet across the arc and into the puddle. The transfer of these droplets occurs through the arc, one droplet per pulse.

With the advanced Pulse MIG, you can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework, very suitable for welding the thin Aluminum sheets.

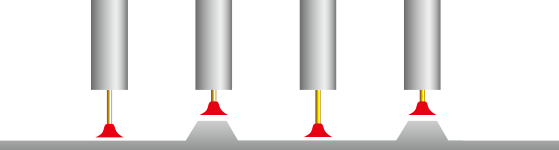

Arc Length control

By changing the distance between torch and workpiece. You can now react much more easily to control the arc, such as changing gap dimensions or arc blow, more intuitively and with greater efficiency!

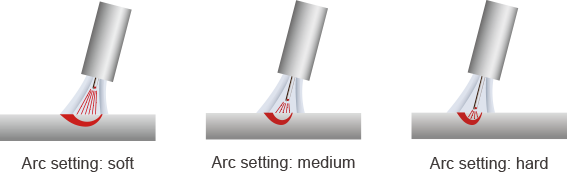

Dynamic control

Dynamic control allows the welder, for the first time, to variably adjust a pulse welding machine to a wide range of jobs and welding positions as well as to his personal preferences. The welder can use a controller to directly access the arc characteristic and change it from soft to hard.

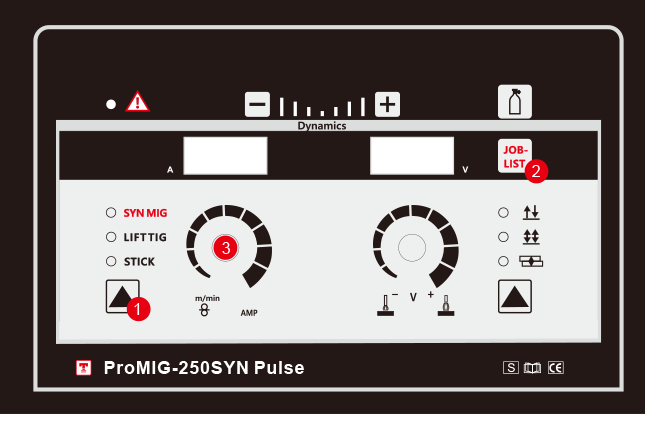

Simple Operation

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function using the material thickness)

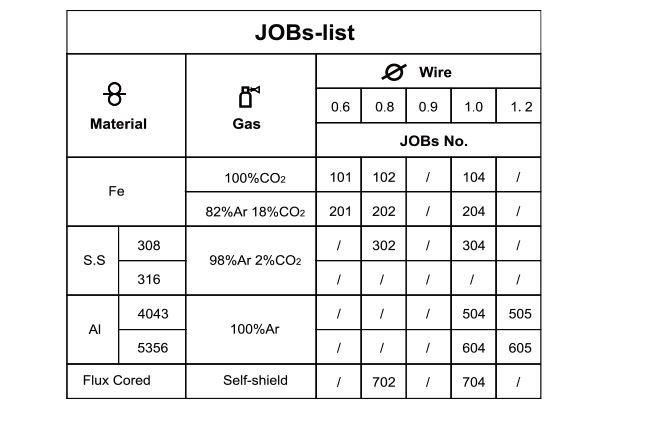

Synergy control with job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

Reliability and Powerful

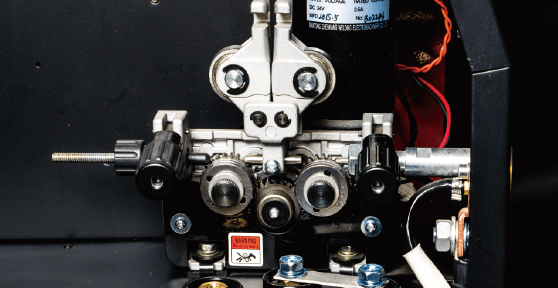

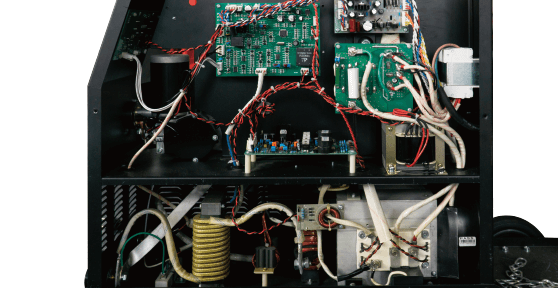

Reliability and powerful, it’s the base of the outstanding performance. ProMIG-250SYN Pulse uses full IGBT Modules Structure. With that it is more reliable than ever and extremely promote the peak amperage up to 450Amps. 4-rollers wire feeder ensures an accurate wire feeding speed to meet the powerful output. Besides, the whole inside structure is tidy and clear, every components are at the right place. It will keep the cooling wind pass through every parts and increase their stability and service life greatly.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号